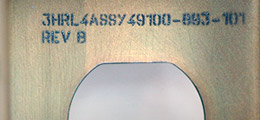

Stenciling

Bloss can perform stenciling operations per Mil-Std-130 using epoxy inks per Mil-I-43553 and A-A-56032. Stenciling is sometimes the only way to mark difficult to reach areas of parts, such as where assemblies have already been put together, or where the marking location prohibits other methods like screenprinting or padprinting. Bloss manufactures all of our brass stencils in house for projects as simple as part numbering, or as complicated as identifying terminals and components mounted deep on the inside of a chassis or enclosure.